Surface treatment and painting - Checking the hydraulic cylinders - Control of the hydraulic cylinders - Cleanliness of the hydraulic cylinders

rigorous engineering has to be followed by a high regularity of the production. For this purpose, HYDRAULIQUE PB creates and produces most of the material needed for the production of its hydraulic cylinders. The company also uses numerically controlled machines and robots.

However, the best machine is nothing without a man to guide it. The multiplication of the functions and the development of learning programs have become key issues of progress.

Thus, the creative competences of the engineering department and the motivation of the workers guarantee quality, while enabling the company to increase its production.

Surface treatment and painting

SA HYDRAULIQUE PB has got an automatic system of good efficiency to paint surfaces. It is composed of:

SA HYDRAULIQUE PB has got an automatic system of good efficiency to paint surfaces. It is composed of:

! a washing machine with detergent, spraying water at 70°C

! a machine to rinse the cylinder, in order to eliminate all the detergent by spraying water which has been conditioned

! a drying oven with forced ventilation to enable the application of a preparatory coat at the adequate temperature

! time for the preparatory coat to dry (25 minutes), in order to avoid that the painting flows

! application of the final coat.

The pieces are dried in a oven with infrared radiations at a temperature around 100°C.

Once dried, the pieces cool down and are arranged on pallets after being unhooked.

With this chain, we are able to meet our commitments as far as the delineation is concerned and to respond to our customers´demands. The paintings we usually use for the final coat are made out of polyurethane. We can either propose paintings for the customer to choose or use the paintings imposed by the customer, at his request.

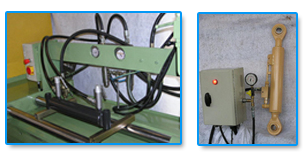

Checking the hydraulic cylinders

Each assembly station is so equipped as to realize a control of tightness with a high pressure gas sampling 40 bars with recycling on all cylinders.

At the request of the customers, or according to the applications, we can make an hydraulic test at a pressure of 350 bars.

Control of the hydraulic cylinders

In order to guarantee the highest regularity of production, various way of checking and measuring are employed. The tools used are calibrated and checked according to the current regulation.

Cleanliness of the hydraulic cylinders

In order to guarantee an optimum cleanliness, Hydraulique PB has got washing cabins specifically designed for the serial washing of pieces.

go top